Used is the best

Knows for a long time that people generate countless quantity wastes, rubbish, and polluted substations. The results of the research by experts are alarming. If we will not come to terms in time and do not start to care about the reduction of generating polluted substations and decompose by long time rubbish, in a short time we will have to get used to seeing a dump behind our window.

Recycling, less waste, and zero waste – in short about what are we getting used to being more eco-friendly in Strefa CNC.

The meaning of the word recycling is probably not necessary for explaining nowadays for anybody, but really popular last time words as zero waste and less waste are still mysterious for a lot of people. Zero Waste and Less Waste are getting famous but how implement these rules in our life? In summary, is going on to get used to generating as little rubbish as is possible. How to do that? Here is a simple way – just to start for changing our habituations. Drop using a plastic tube during visiting in a restaurant, purchases of well quality ecological bags made out cotton or materials come from recycling and using them during shopping every day, avoid to dring water from a plastic bottle, choose them from the filter – it is an only few simple examples you can use in your life, and using them every day by all year makes reduce generating rubbish and wastes. You can ask how whit this everything in the business doing to sell used machines. We will explain it in short in this article today.

The second life of the used machine

Purchase a new machine for wood processing – veneer, drill, or CNC machines or however other technologies is connected with producing a new device and element of the casing. The new machine of Homag Group is working for a customer mostly by a few or several years without any break. After this time many customers decide to change machine on a new one by any reason – because of current machine is not too much efficient to keep up for getting bigger production by the years, or maybe customer needs more modern technology or other improvements which are guaranteed only by purchase a new machine. And now is the question what should we do whit the current machine? Does not exist any other solution for a customer than disposal or scrapping used machine, because after several years it is completely exploited? Not necessarily.

Choose used, means less waste in your plant

Machines of Homag Group are well quality tools, it means that after overhaul the machines will work for another customer by next several years. Many parts of the machine need only cleaning, conservation, and refreshing because even if they are working for several years are not served wear (e.g. case part). In Strefa CNC we care about machine after overhaul can be used by the customer by the next several years. It means we have checked every part of machine needings exchange for a new one and we overhaul in the next step. Thanks to that, after a few months of intense work our team, cooperating with the service of Homag Group, can offer our customer full texted tool in quality the same as has a new one machine of Homag Group. This way we launch a new machine which will work for new customer by several years. So that is not necessary to the scrapping of used machine, instead of a few tone wastes, we generate only that made by exchanging used part for a new one. This is exactly like an idea of less waste, isn’t it?

Cleaning by dry ice

In an article today we want to tell something about ecology, and more about our activities on improving situation our planet. As a brand, we are getting used to being conscious of corporate social responsibility We hope that by our activities and involving we get case in point. Today we will tell about this part of work at the machine is cleaning.

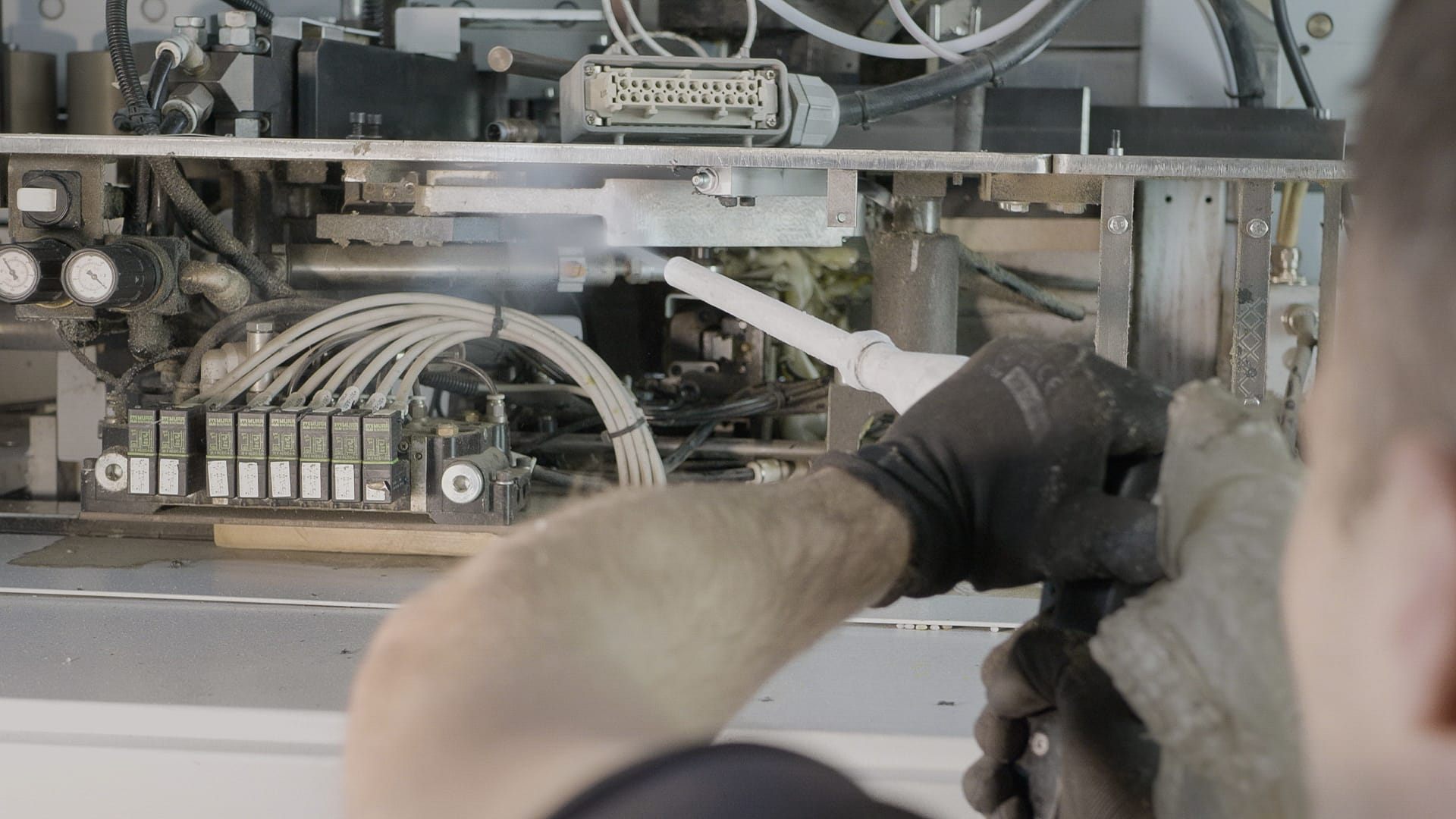

Before we will start to renovate the machine we clean it removing stains and dirty made by the exploitation machine for several years. Currently exist many opportunities for cleaning different kinds of devices. Because of special kind of our profession, we can’t use water or sand for cleaning machines. We are conscious about ecology, so we don’t use in our processing substations which would generate production toxic wastewater and dirty, unsuitable for recycling cleaning cloth. In process of cleaning the machine, we don’t use toxic intermediates, solvents, detergents, or other chemicals.

So how do we clean our machines?

Cleaning by the dry ice is the first stage of work with machines. The machine working for several years has many contaminations, residues of glue, half-product, preservatives, and many more another different kind of contaminations. Cleaning by using dry ice leads us for overcleaning any contamination without needs making cleaning after cleaning, how it is by sandblasting.

How cleaning by dry ice is working?

Dry ice is a product in the form of pellets. The first part of cleaning is compensation, next under pressure cells achieve a speed higher than 150 m/s. Pellet has a low temperature (about – 79 Celcius grad), whit this reason and kinetic energy followed by getting low flexible, and in consequence cracking detachment contamination. Detached cells are transformed in form of liquid to gaseous. In this process, contaminations will be detached in so sensitive way it will not results in damages to the surface area.

Cleaning by the dry ice is eco-friendly because:

during the process are not used harmful substances, intermediates, chemicals, and solvents.

not makes generating secondary wastes like empty solvent containers, dirty cleaning cloth, and toxic wastewater.

simply disposal is the next advantage of cleaning by dry ice. After finished cleaning by dry ice only what is necessary to do is to wipe up dirt, which can just sweep or vacuum off the floor.

By cleaning by the dry ice we avoid generating additional wastes, don’t use pollute substantial, and contribute to improved quality of the environment, by limiting waste production.